A WORKING MAN’S AFRICAN DOUBLE

Chapter 1: The Gun

Russ Gould

In this series of

articles, the author explores the concept and actual performance of an

affordable double rifle of sufficient power to handle large African game. This

first episode explains the concept and provides an overview of future articles

describing actual hunts undertaken to prove the efficacy and find the limits of

the cartridge/rifle combination.

That contemporary African Safaris are more affordable now

than ever before is no longer a secret. The rapid development of the Safari

industry, especially in

The vast majority of hunters availing themselves of this

good-news situation are not

What aspiring or accomplished African hunter, however, has not dreamed about using a traditional double rifle on his or her next hunt? Aside from the romance of twinned rifled barrels and those very sexy express sights, there is a very practical advantage to using a gun of such robust and inherently reliable design. First, each barrel is actually a separate mechanism largely independent of the other. The design incorporates redundancy, allowing the hunt to proceed if, for example, a firing pin were to break or a cartridge were to misfire. And given the tough (and in some cases, dangerous) nature of African species, having a quick reliable second shot available without having to operate any mechanism is a real advantage. In many cases, when a second shot is called for, the hunter does not have the time to operate a bolt. (Semi-automatic rifles are prohibited in most African countries, ruling out the modern answer to the need for two or more quick shots at a rapidly disappearing or -gulp- approaching quarry.)

|

|

|

Author on Safari in

|

Such a rifle should be in a reasonably powerful caliber. While today’s hunter is more likely to use his rifle on plains game up to and including the 2000 lb plus Eland, he will surely want to have enough power to take that once-in-a-career Buffalo if and when his ship comes in. So when we speak of an African Double, we dismiss the inexpensive imports such as the EAA double in 30-06 or similar calibers. No, here we are talking about fat cartridges and barrels with more hole than metal.

The rapidly rising prices of heavy caliber double rifles attests to the advantages offered by and additional satisfaction gained from going afield with one . The price of a good English double rifle of sufficient power to be classed as a Safari rifle is now well beyond the reach of the average would-be Ruark. Even the more affordable vintage black powder doubles in 577 or the various 450 calibers, or the modern Chapuis and Merkel side-by-sides are more expensive than the average hunt, making such a weapon merely a fantasy for most contemporary hunters.

Happily, there are more affordable options for those who cannot afford an Alexander Henry in 450/400 or a Krieghoff in 470 Nitro Express. One such option is the excellent Valmet 412 or 512 “Shooting System”, comprising a universal over/under receiver that accepts various double rifle, rifle/shotgun combination, or shotgun barrels. The compactness of the take-down double, and the versatility of such a system is especially appreciated by the traveling hunter, who may well want to avail himself of the excellent bird shooting now offered as an adjunct to many hunts.

The author jumped at the opportunity to purchase just such a gun offered for sale on an internet classified site: a little-used, earlier 412 version, with a set of double rifle barrels in caliber 375 Winchester with the excellent Valmet quick-detachable scope mount and scope fitted, plus a spare set of 12 ga barrels choked modified and full, all in a hard case just large enough to accommodate all the bits while still small enough to fit in the lower compartment of a Boyt sportsman’s duffle bag. The price for the entire ensemble was $1500, about what it would cost to purchase a quality used bolt rifle and over/under shotgun. With rifle barrels mounted, the gun weighs a modest 9.5 lbs with scope and sling attached, quite substantial compared to the mountain rifles so popular today, but very handy in comparison to the typical 10 to 12 lb heavy double.

|

|

|

Valmet “System” allows rifle barrels, shotgun barrels, and combinations to

be fitted to the same receiver in a compact ensemble ideal for Safari travel. |

Recognizing that the 375

The case capacity of the 375/444 is about 10% less than that

of the 375 Scovill/Hawk wildcats, both based on the

30-06 case, and obviously quite a lot less than the 375 H&H case. Think of

it as a ‘light’ 375 that fills the gap between the obsolescent 375

|

|

|

Photograph shows the 375/444 case (left) as loaded with the 235 gr Speer Soft Point, next to the same bullet loaded in

the 375 Winchester case. The larger case is capable of velocities in the

2300-2500 fps range, in comparison to 1900-2000 fps in the 375 |

While on the subject of calibers, it should be noted that Valmet (now branded Finn Classic by the Italian company

that purchased the rights to manufacture the rifle from Valmet)

no longer produces the 375

This rifle is an over/under double with some nice features. In addition to the interchangeable barrels and quick-detachable scope mounts already mentioned, the barrel regulation can be adjusted simply in both the vertical and horizontal planes with a screwdriver. The vertical alignment is adjusted by sliding a collar on the lower barrel that interacts with a wedge on the upper barrel. This adjustment is hidden by the forearm. Horizontal alignment is controlled by means of two opposing screws at the muzzle. Both adjustments are set at the factory and the initial positions are marked by means of a linear stamping that crosses the fault line on the two mechanisms. This innovative approach to regulation allows the user to select whatever factory or home load preferred and to regulate the rifle for that load at the time the rifle is sighted in. This is not possible with traditional doubles, which are regulated by the maker for a specific bullet and load and soldered in place.

|

|

|

|

Vertical regulation is adjustable via a sliding collar/wedge device

that bends the barrels toward or away from one another |

Horizontal regulation is adjustable at the muzzles |

Further features on the rifle are powerful ejectors, a sleek full length rib with one adjustable folding rear leaf, single selective trigger, and cocking indicators just aft of the sliding tang safety. A selector in the trigger itself determines the firing sequence. Normal sequence is bottom barrel first, as firing this barrel puts least stress on the action and the first barrel is fired many more times than the second. The barrels are a full 24” long but the rifle is nevertheless shorter and lighter than most standard bolt rifles, due to the break-open mechanism and the slender contour of the barrels themselves. All metal parts are highly polished, handsomely blued steel, and the stocks are well checkered walnut with an attractive and practical satin finish. The receiver sports a simple gold-filled border motif that complements the lines of the receiver itself. Current production rifles are also available in satin nickel and high gloss nickel in a deluxe version (very shiny and to be avoided at all costs). At one time, different stock finishes were offered but it appears that only satin is now offered by the manufacturer.

|

|

|

Original chambering was 375 |

There are two minor faults that detract from the many positive features of the gun. First, the metal surfaces including the barrels are too reflective. The flat sides of the receiver act like mirrors, and there is twice the barrel surface to broadcast to the ever-alert game that the Mlungu is coming. Safaris are generally conducted in sunny climates and gloss finishes, particularly on barrels, are give-aways. To overcome this to some degree, the author found that carrying the rifle slung over a shoulder in the muzzle-down orientation with the trigger to the front was not only comfortable, but kept the barrels out of sight, the action tight against the body, and the trigger protected by the elbow. The sling was reversed with the wide section near the butt and adjusted so the forend could be cradled in the hand with the barrels between the first and second fingers, sharing the load with the shoulder. Thus, the gun could be carried all day without discomfort, something that cannot be said of most doubles, and reflections were minimized. Second, the trigger, while crisp, was heavier than necessary and is not obviously adjustable. The heavy trigger raised it’s ugly head more than once during initial field testing as will be explained later, and this will be remedied before the rifle is hunted again.

Once the decision regarding caliber was made, a reamer and

dies were obtained with some difficulty and after considerable confusion about

the actual dimensions of the factory round was cleared up. Since the 375JDJ is

a proprietary cartridge licenced only to

While the rifle was being rechambered

by Ken Owen, a supply of cases was very easily formed in one step from 444

Marlin brass with the

There is no load data available for the 375/444 in a rifle barrel. Hornady publishes data for the pistol cartridge in their excellent manual, and anecdotal loads are available from various sources. Reloader 15, IMR 4064 and 4198, and H322 and 4895 were commonly cited as suitable for this cartridge in 14” pistol barrels with light and medium weight bullets. After reviewing the powder recommendations and evaluating powder stocks on hand, the author decided to use W748 powder with the 235 grain bullet, even though most sources introduce this powder only for bullets in the 300 grain range. Right or wrong, it was thought that the longer barrels call for a slower powder with a light-for-caliber bullet than those suggested for the 14” pistol barrel for which most published loads are intended.

Due to die/reamer supply problems, the barrels arrived back from Ken’s shop with about a week remaining before departure, limiting the amount of experimentation that could be done. A Simmons 1.5x-5x 32mm scope that was purchased with the rifle already mounted in the one piece quick-detachable Valmet mount was fitted to the barrels and tested for alignment at 25 yards. After minor adjustment, the 100 yard target was engaged firing each barrel in sequence. Starting at 49 grains with absolutely no sign of pressure, testing commenced and loads were increased gradually. Recoil was noticeable from the bench (as it is with any caliber heavier than a 308) but nowhere near the pain threshold.

|

|

|

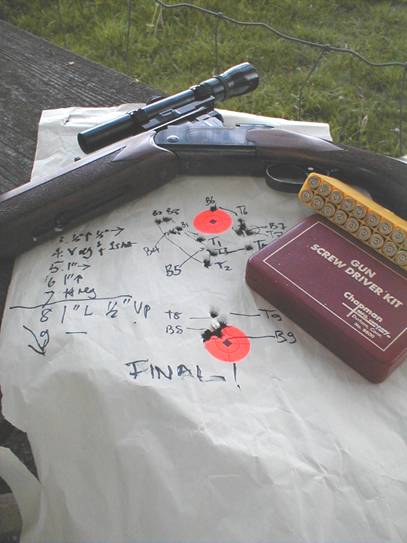

Author’s stand-up

shooting bench showing rifle ready for test-firing. Note chronograph and

micrometer. |

Muzzle velocities were recorded separately for each barrel and for each increment of powder. Before and after each firing, case heads were miked and primers inspected for pressure. Adjustments to the regulation were found necessary and were made as testing progressed, by trial and error. Relatively small movements (half a turn of the regulation screws) were made and had a visible effect on the target. At 53 grains (well above the recommended load for the weaker Contender action with 250 grain bullets), velocities of 2300 fps were obtained and there was still no sign of excessive pressure.

|

|

|

Cases were carefully miked before and after firing to detect incipient pressure signs. |

Case heads showed .001 expansion (very mild) and primers were round with no cratering of the pin indentation. Inspection of the bore showed no sign of unburned powder, although there was some deviation in muzzle velocities. Considerable difficulty was encountered with the scope adjustments however, until the author discovered after about 60 rounds had been fired that the scope had visible parallax error. Since no adjustment is possible on the Simmons, a rather old but well-loved steel tube Weaver V4.5 was substituted and the holes started to obey adjustment. After fine-tuning the regulation of the barrels and adjusting the scope, accuracy was astonishing, with composite groups measuring just under an inch at 100 yards. Unfortunately, the heavier Nosler bullets did not shoot to the same point of aim as the primary load, nor were the barrels in regulation for with that bullet. The Noslers cross-fired significantly, with the bottom barrel printing about four inches above the top barrel, in defiance of conventional logic. Normally, heavier bullets tend to disperse rather than cross due to the effects of recoil. In addition, the Nosler bullet has a boat tail design, intruding into the limited case capacity. Further testing of heavier bullets was therefore deferred until necessary.

|

|

|

Accuracy and regulation were way better than expected. |

There was ample room in the case for 3 to 5 more grains of powder and no obvious signs of pressure at 53 grains, but common sense prevailed and 40 rounds were loaded and packed ready for the long flight across country and then across the Atlantic for Phase I of the field test. Before departing, a ballistics program was used to establish the theoretical trajectory of the load, separately for each barrel as the sight height is by definition different. The program indicated the following trajectories:

|

Yards |

Top |

Bottom |

|

0 |

-2 |

-3 |

|

50 |

.1 |

-1 |

|

100 |

.5 |

.5 |

|

150 |

-1 |

-.8 |

|

200 |

-4.6 |

-3.2 |

In the next article in

this series, the author tests the 375/444 double on Impala, Warthog, and Nyala in the riverine brush and

Acacia woodlands of

Russ Gould is owner

and operator of Double Gun Headquarters (Doublegunhq.com), a multiseller virtual gunshow

specializing in fine double rifles and shotguns. He also offers African Safaris

with personally selected operators to

Copyright R. Gould 2014. All Rights Reserved